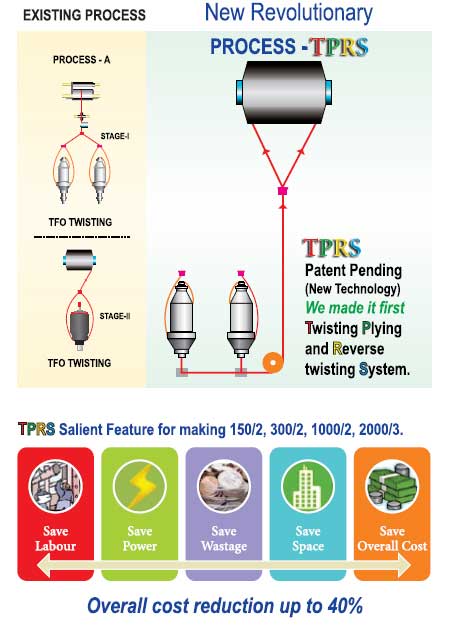

Being a Trend Setter in yarn twisting technology this is a very special phase for Meera Industries, Surat, India. We proudly want to announce that after research of several years we could invent the World's First SINGLE STEP S/Z Twisting Machines (TPRS Twister).

All kind of doubling yarns like Carpet yarn, Embroidery Yarn, Fish Net Yarn, Sewing thread, Quilting thread, Salvage yarn, Tyre cord or any other double/triple yarn can be manufactured in a single step i.e. from COPS WINDER TO FINISH PACKAGE.

Meera's one step TPRS manufacturing method would give several Qualitative, Operational, Capital and Cost advantages.

APPLICATION :-

BELOW IS THE GENERAL IDEA OF AN OLD AND NEW PROCESS OF MANUFACTURING DOUBLING YARN :-

SUPERIOR QUALITY :-

The Quality of the yam manufactured through TPRS technology has better quality than all previous technologies. This is because of the reverse twisting is taking place under the uniform tension of individual pre-twisted yam. Hence the placing of yarn during final hvist is most uniform than any other process.

SPACE SAVINGS :-

TPRS Technology not only reduces the operational cost instead it a. helps in various ways to reduce your capital cost.

SMOOTH RUNNING :-

The beauty of the process will be realised in smooth running of the machines with very minimal breakages and dean environment in the work area.

LABOUR ADVANTAGE :-

Currently the industry's biggest worries are to manage labour shortages and the Launch of TPRS at this crucial time would definitely help manufacturer to solve this to a greater extent.

Above was just a brief summary of TPRS technology, for more details and machine demonstration you can visit our factory.

TPRS TWISTER MACHINE (FOR ANY "S" & "Z" TWIST YARN)

TECHNICAL SPECIFICATIONS :-

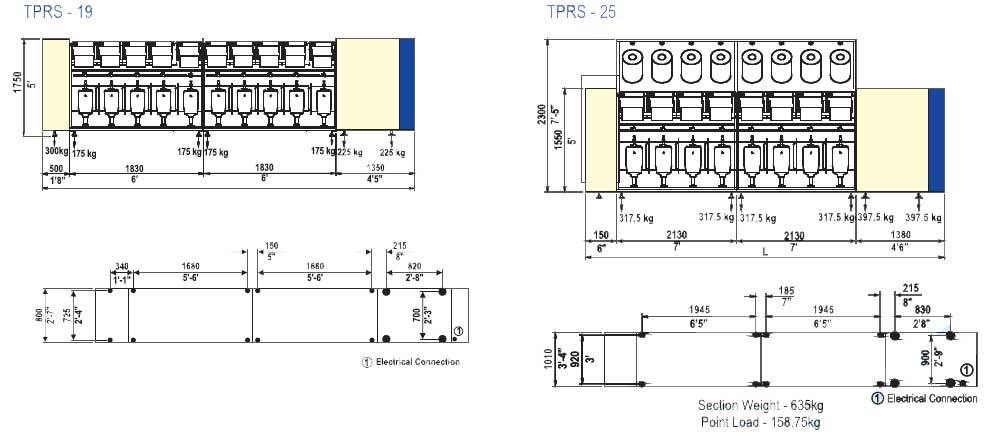

| (TPRS -19) | (TPRS - 25 MOTORISED) | |||||

| FRAME | Single deck both sides | Single deck both sides | ||||

| MACHINE WIDTH | 800 mm | 1010 mm | ||||

| SECTION PITCH | 1830 mm | 2130 mm | ||||

| MACHINE HEIGHT | 1750 mm | 2300 mm | ||||

| DENIER RANGE | 100 to 600 denier | 600 to 4500 denier | ||||

| TWIST RANGE | 150 to 1. t/m, yam speed shall be set at max 70 mtrs/mm | 50 to 1500 t/m, yam speed shall be set at max 70 mtrs/mm | ||||

| MOTOR PULLEY | Set of 6000 to 10000 rpm | 2000 to 5000 Invertor Controlled | ||||

| SPINDLE BELT / DRIVING | Endless belt with nylon rpm | Individual motor spindle | ||||

| ATTACHMENTS | RPM, TPM, M/MIN display, Yarn feed stop at yarn breakage, Anti - Patterning device | RPM, TPM, M/MIN display, Yarn feed stop at yarn breakage, Anti - Patterning device | ||||

| SPINDLE PITCH | 360 mm | 525 mm | ||||

| SPINDLE /SECTION | 10 | 8 | ||||

| NO. OF SECTION | 8 | 10 | 12 | 8 | 10 | 12 |

| NO. OF SPINDLE / DECK | 80 | 100 | 120 | 64 | 80 | 96 |

| CONNECTED LOAD PER DECK | 12.5kW | 12.5kW | 15kW | 32kW | 40kW | 48kW |

| LENGTH IN FEETS | 53' | 65' | 77' | 61' | 75' | 89' |

| LENGTH IN MTRS. | 16.20 | 19.80 | 23.50 | 18.60 | 22.90 | 27.10 |

SUPPLY PACKAGE :-

| TPRS -19 | TPRS - 25 | |

| SUPPLY PACKAGE | 32 x 36 x 360 mm cops | 32 x 36 x 360 Flanged bottle |

| SUPPLY PACK. WTG. | 1 kg. | 1.6 kg. |

| NO. OF PLY | 2 or 3 Ply | 2 or 3 Ply |

TAKE - UP PACKAGE :-

| TPRS -19 | TPRS - 25 | |

| PACKAGE CAP. | 1.5 kg knotless | 2.5 kg knotless |

| PACKAGE CAP. | Take up 3.5 kg. with knot | Take up 5 kg. with knot |

| MAX PACK DIA | 250 mm | 300 mm |

| PACKAGE TUBE | Dia 46 x 57 x 230 | Dia 46 x 57 x 290 |

DIMENTIONS :-